Fulfilling Recycling Plant Expansion with Design and Assembly Expertise

Our client in the recycling industry aimed to expand their plant by 50% and turned to us for design and assembly assistance.

The Challenge

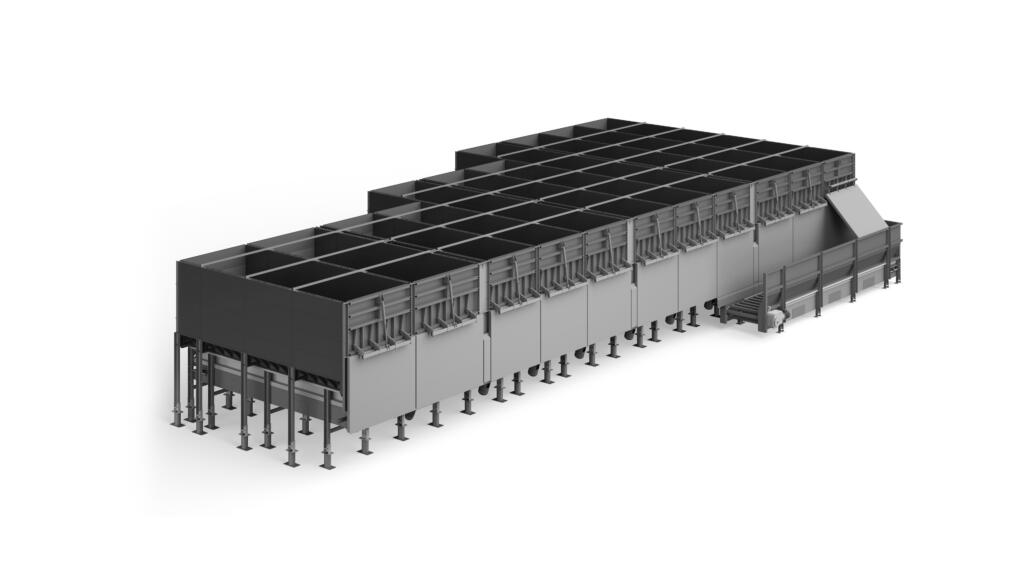

In a challenging installation scenario where access was limited due to the presence of an existing mezzanine floor, a modular design approach was adopted to ensure successful implementation. The project faced an additional constraint as crane access was not available to the customer, necessitating careful design considerations. Despite these challenges, the team worked diligently within a tight timeline to deliver the desired results.

Given the bespoke nature of the project, multiple design solutions had to be developed and approved by the customer before proceeding with manufacturing. This step ensured that the final product met the specific requirements and expectations of the customer. Through effective collaboration and meticulous attention to detail, the project was successfully executed, overcoming access limitations and fulfilling the client's vision within the given timeframe.

Our solution

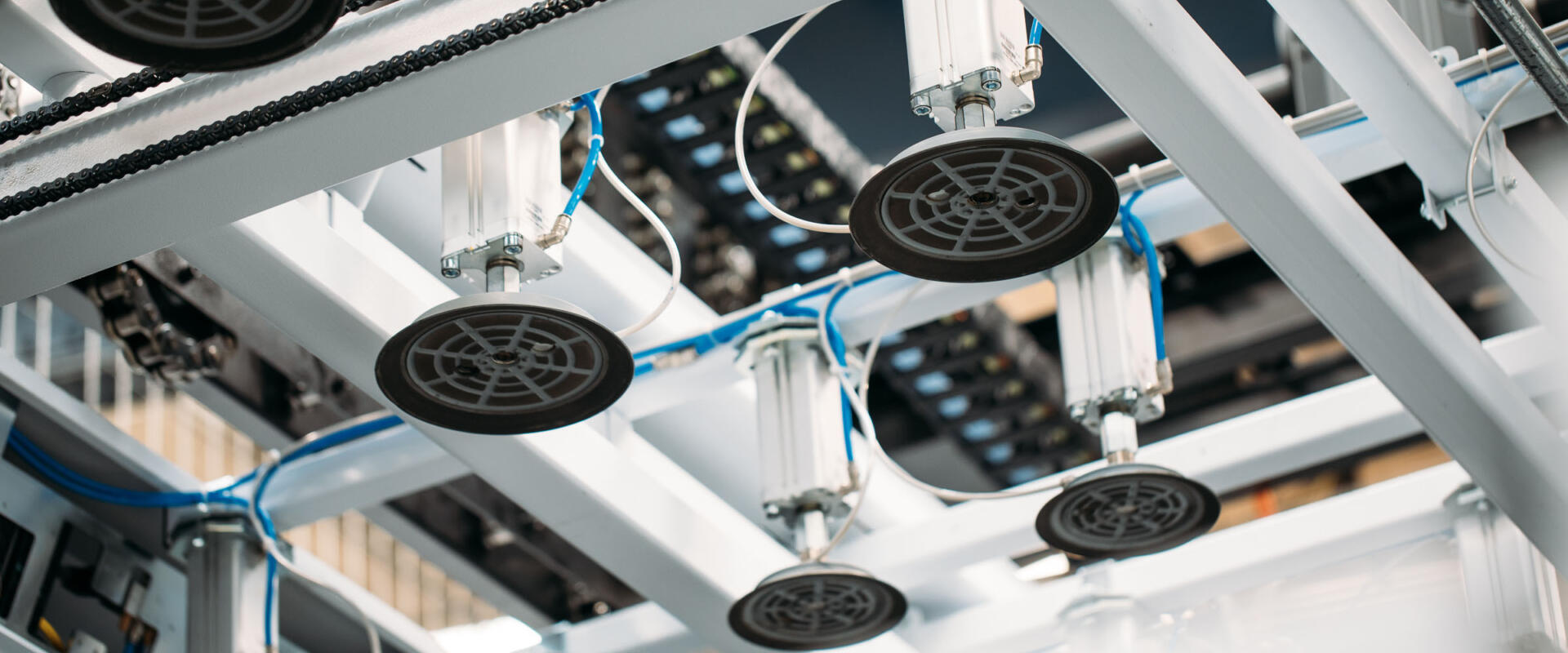

To address limited access during installation, a modular approach was chosen, simplifying the process. Close collaboration with the customer spanned from design to installation, ensuring the solution exceeded expectations. Just-in-time production was implemented to meet the client's tight deadlines.

Additionally, a new hydraulic door system replaced the existing prone-to-wear guillotine doors, while a modular bunker wall system was proposed to facilitate installation by the customer's own team.

Results

Our collaboration with the client resulted in a significant 50% increase in waste processing capability, thanks to their new unmanned and highly automated waste sorting technology integrated with our installation. This advancement enabled the customer to expand their operations and process a broader range of plastic products, aligning with their commitment to providing environmentally friendly services.

Together, we achieved enhanced efficiency and capacity, empowering the client to meet growing demands while contributing to a more sustainable future.